Welcome

Geopolytex’s Non-Woven Geotextiles are 100% Polypropylene staple fibres, which are randomly formed for Dimensional Stability. Geopolytex offers a non-woven 200g per square meter for use in civil and environmental applications.

In environmental applications they are used as a protective cushion under or above geomembrane liners to prevent the risk of puncturing from coarse aggregate rock on top and serves as a barrier for grass and weed protection.

In civil construction, geotextiles work to prevent intermixing of sub-base soils with granular layers and help filter surface water to prevent stones and soil particles from passing and migrating or contaminating into the sub-base.

Geotechnical, environmental and civil engineering projects typically involve an assessment of soil characteristics. Most often, non-woven products are used to help make soils more suitable for construction. This includes products that provide filtration and soil separation functions. Geotextiles are the most effective product solution for filtration and soil separation. They act as a separation layer between the sub-base soil and over topping aggregate to prevent intermixing of the two. Preventing this intermixing helps ensure structural integrity of construction projects while avoiding aggregate loss. Geotextiles can also minimize the risk of soil particles migrating into the sub-base from surface water by acting as filter. This soil filtration helps also helps preserve structural integrity.

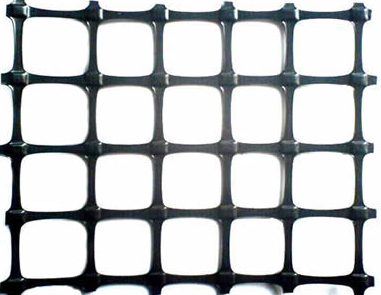

Geopolytex’s Biaxial Geogrid is a geosynthetic compound made out of polypropylene polymers and are primarily used to reinforce and stabilise soils. They are made through a series of procedures including crossway stretching, lengthway stretching and extruding. This production process ensures that all the geogrids have high tension resistance along with a high tensile strength, which therefore increases the overall bearing force that the geogrids are capable of.

If the soil in the area where you will be adding a dense load (such as slabs, railway sleepers, trucks or lorries) is too soft, the pressure will force the soil to warp. A Geogrid will help to secure the soil through compacting the aggregate which furthermore enhances the bearing capacity of the underlying ground.

Unlike when the load is introduced to the soil alone, the geogrid forces the heavy load’s pressure to be spread over the entire surface area of the grid, due to the subgrade having strength in both directions.

This essentially means once the Biaxial geogrid is set out and the heavy load is put in place the soil beneath the grid compacts and the subrade’s strength is further enhanced. This means that it is very cost effective by saving both labour and maintenance expenses.